ECOPULPING Mills

From straw to unbleached pulp

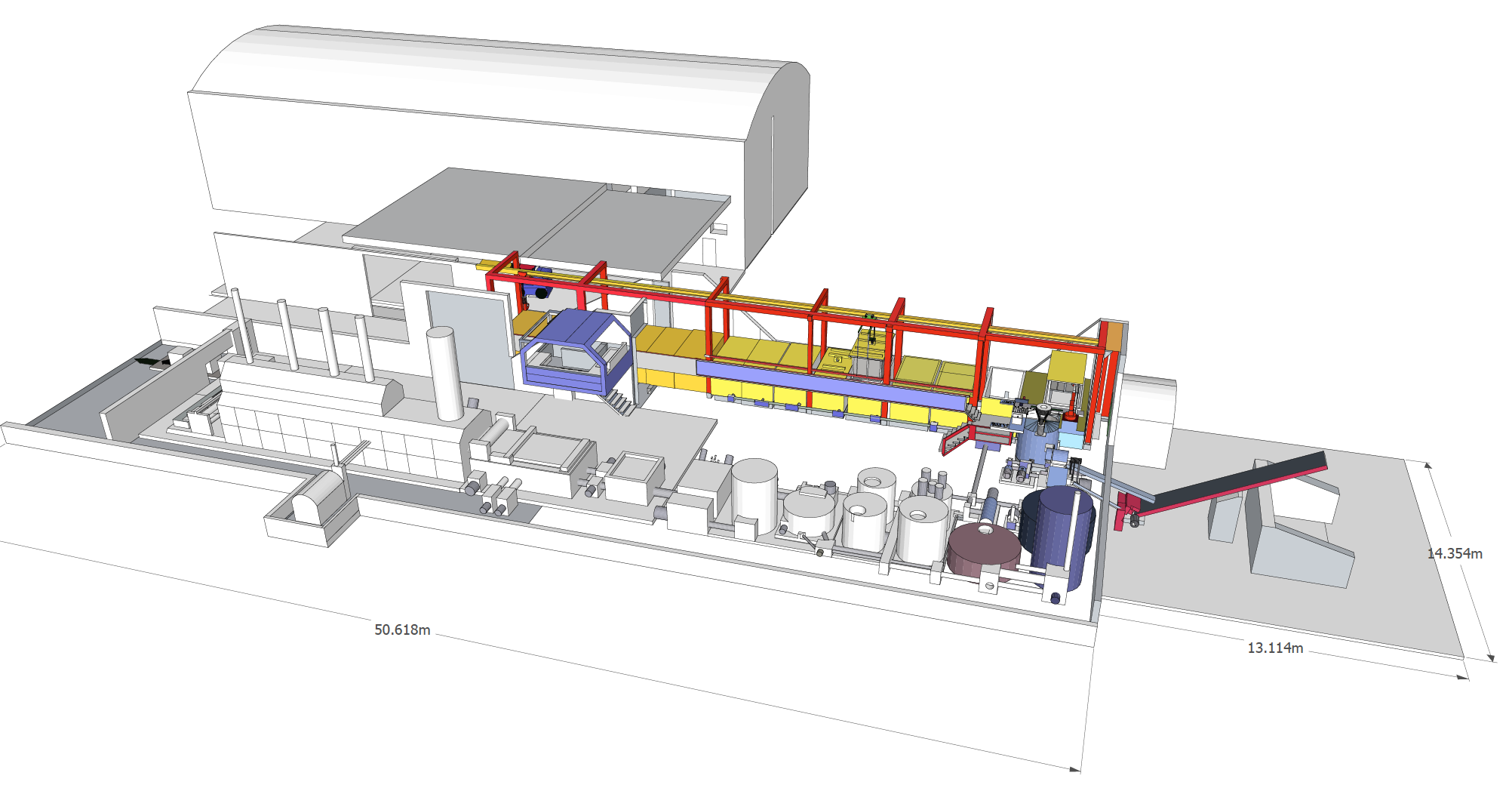

ECOPULPING can be installed as an independent unit to produce marketable unbleached pulp, or can be retrofitted to paper mills (close to straw production) to produce Paper, different types of Packaging or tissue from straw, some of which will need to be mixed with high grade recycled pulp or virgin pulp.

The ECOPULPING mills produce pulp but also valuable by-products with different applications, one of which being soil conditioner or fertiliser that can be used by farmers.

The capacity of these mills can vary from small to medium, 10 to 400 tonnes unbleached pulp per day, the straw being supplied within a 50 miles radius.

From straw to unbleached semi-cleaned straw pulp – Project I

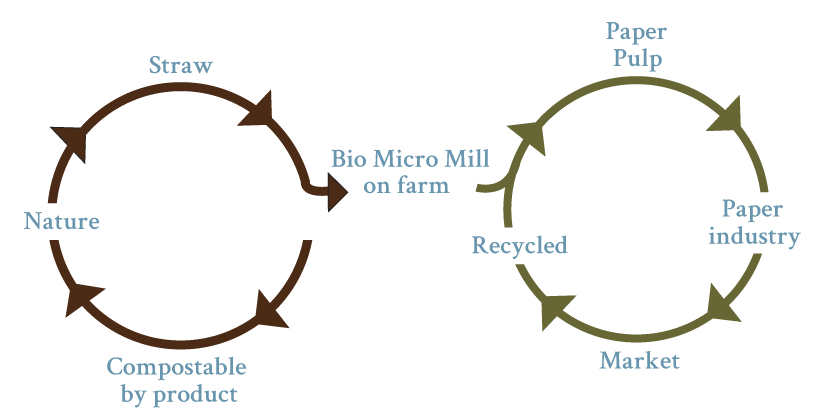

ECOPULPING can have a small or medium capacity and be installed on or near the farms where the straw is produced and transform the straw into an unbleached semi-cleaned paper pulp.

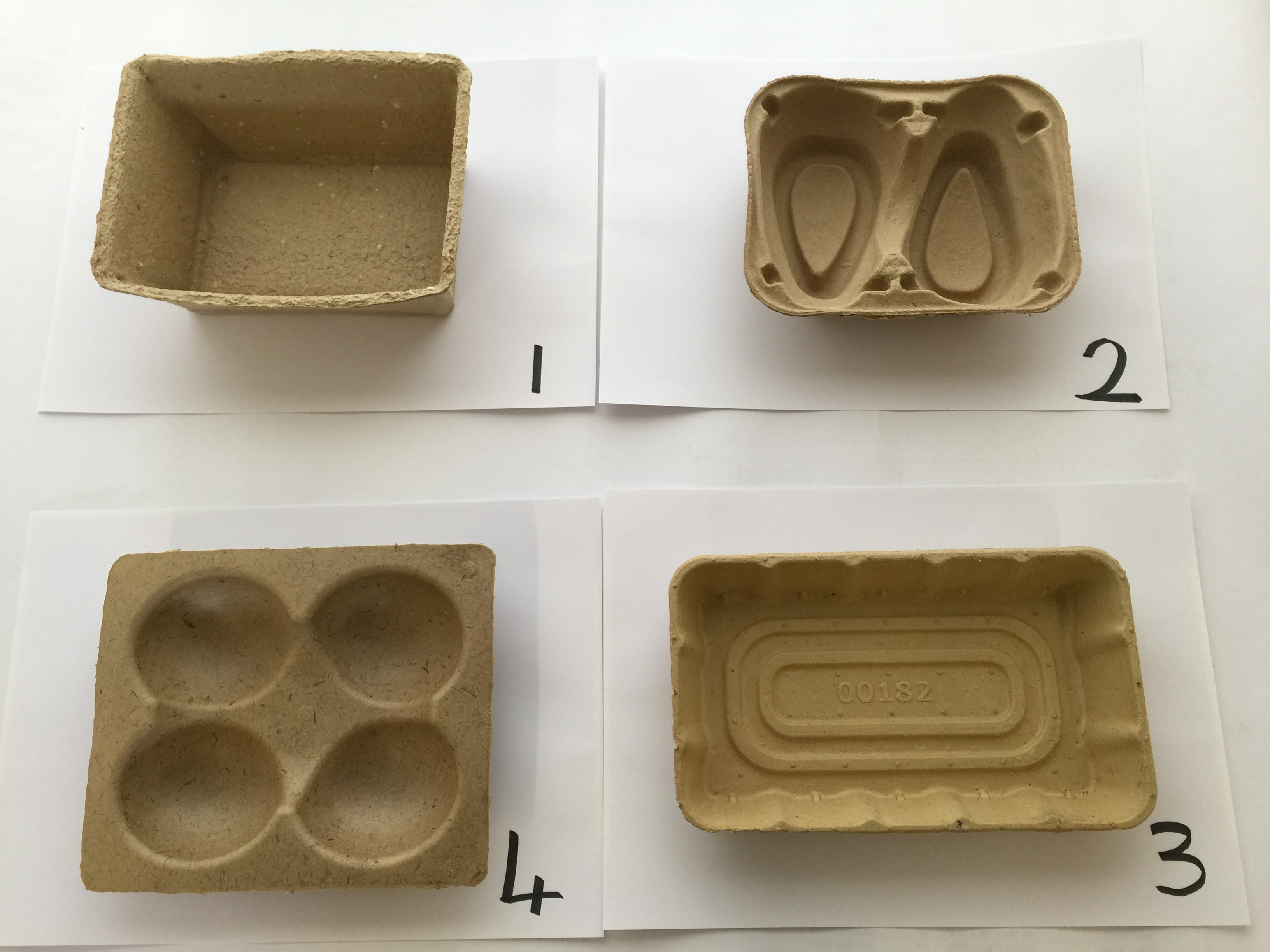

The unbleached straw pulp can be used for corrugated or other types of paper used for packaging, or for moulded packaging products.

Our small demonstrator is currently producing small quantities of this pulp, and a larger capacity demonstrator mill is planned to start producing in 2019 – we have now secured funding for this project.

From straw to unbleached straw pulp – Project II

The ECOPULPING Mills producing unbleached straw Paper Pulp and valuable by-products.

The by-products can have different applications, one of which being soil conditioner or fertiliser that can be used by farmers, but also as raw material for moulded packaging when mixed with other fibres, and for some other valuable applications.

The ECOPULPING Mills can have a small or medium capacity and can be installed on or near the farms where the straw is produced.

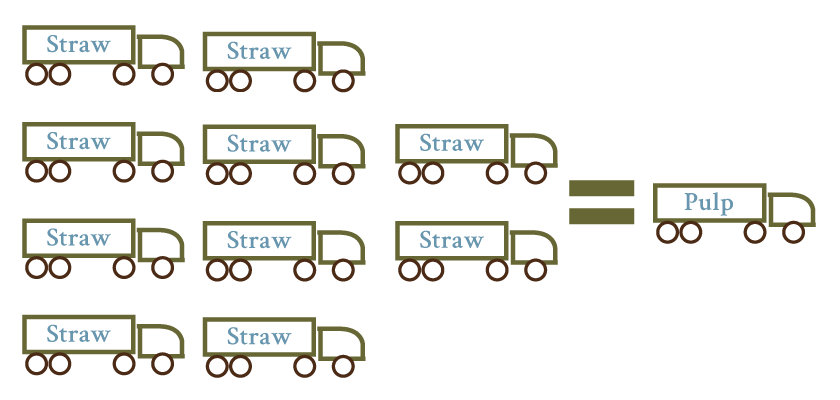

For higher capacities, Nafici Environmental Research’s concept is to divide the process in two parts:

– One part producing the unbleached semi-cleaned pulp, near the source of straw

– the second part being a central unit processing the unbleached semi-cleaned pulp to transform it into a cleaned unbleached and eventually bleached pulp or directly to paper or packaging.

This avoids transport of bulky straw. It’s a much lower volume of pulp that is then transported.

Unbleached cleaned straw pulp is currently available only in very small quantity and a larger scale production is planned to start production at the end of in 2019.

The advantages of this innovative process are:

-

No more transport of bulky straw

-

50% less energy used compared to existing processes

-

minimum 30% less investment and operational costs

-

no Waste, no odour

-

ECOPULPING Mills are designed to be farm located

-

The process and equipment can be operated easily

-

Capacity can be adapted to the size of the farms

-

The by-product can be sold as a soil conditioner, fertiliser or as raw material for moulded packaging.

Copyright © Nafici Environmental Research Ltd | All rights reserved

Website by BritWeb